Our client, a world leader in PLS and custom rubber lip seal design and manufacture, caters to high-performance industries such as Formula One. They sought to implement a digital solution for viewing the current job progress on their manufacturing machines to enhance operational efficiency and real-time monitoring.

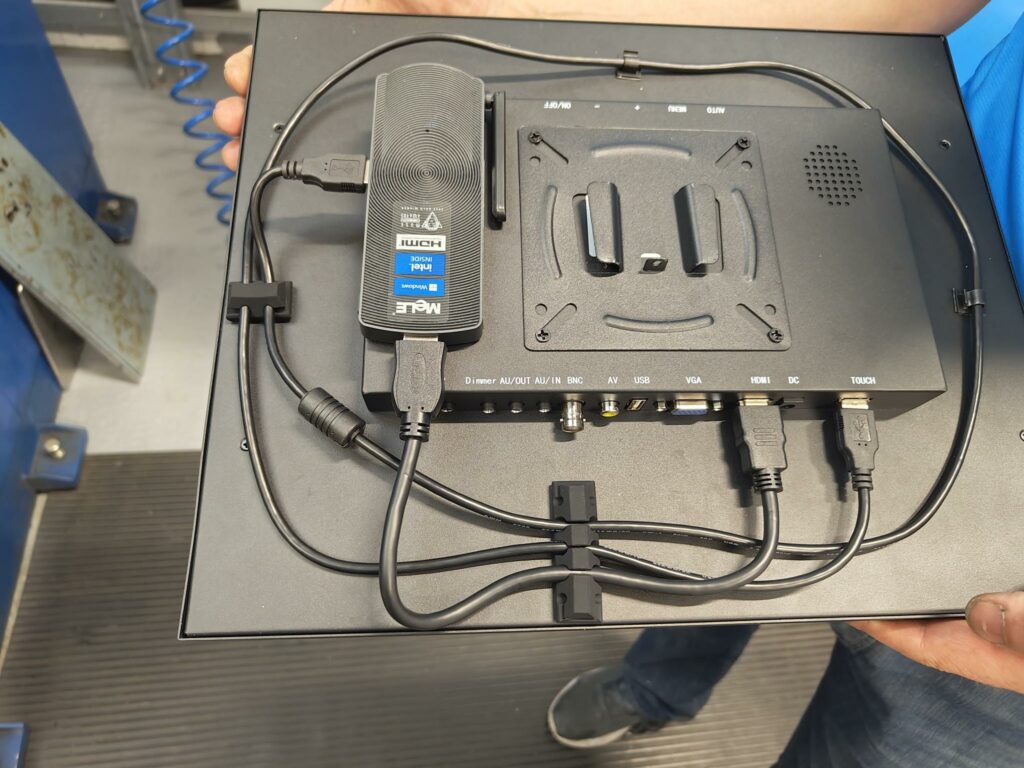

Our Solution: Understanding the critical nature of their operations, we advised on the most suitable displays and micro-form-factor computers to meet their specific requirements. We proposed a comprehensive solution that included high-resolution, touch-screen monitors to provide clear and interactive displays of job progress.

Implementation Process: After consulting with the client, we developed a detailed proposal outlining the recommended hardware. We walked the client through the proposed solution, ensuring all aspects met their needs and addressing any concerns they had. Once the proposal was approved and signed, we promptly ordered all the necessary components.

In our office, we carefully assembled and configured the units. This included rigorous testing of the displays to ensure they met the client’s exacting standards. After confirming the equipment’s performance, we transported it to the client’s site for installation.

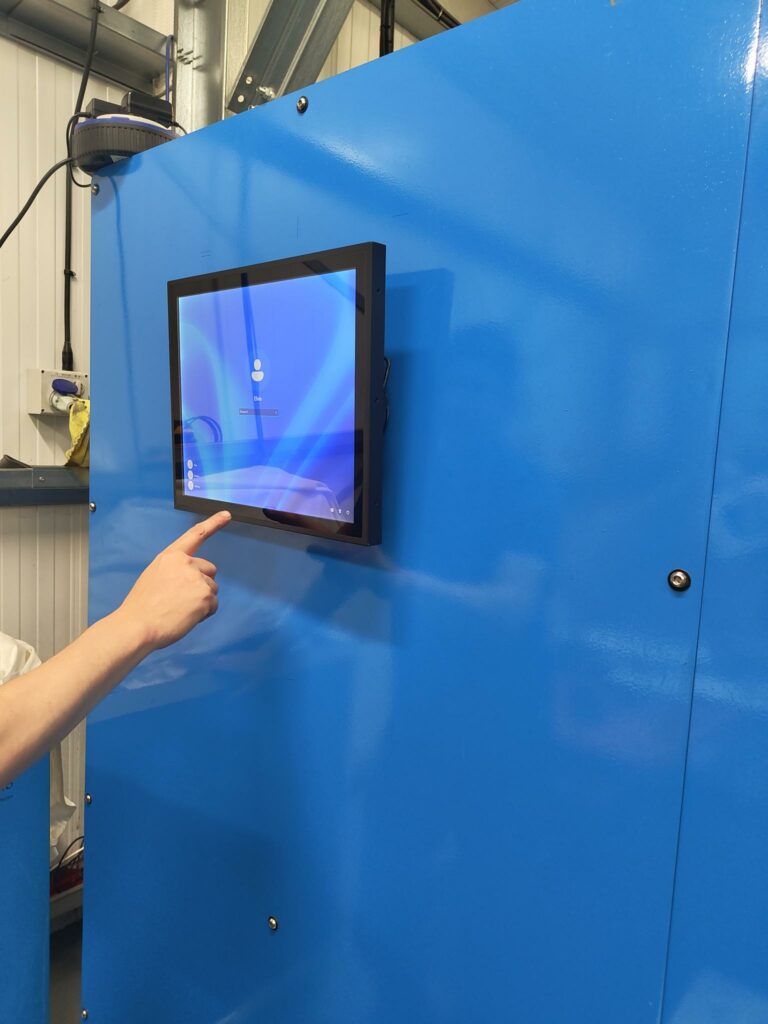

On-site, we completed the final setup and configuration, ensuring seamless integration with their existing manufacturing systems. Our team worked closely with the client during this process, providing hands-on training and support to ensure they were comfortable with the new digital display setup.

Outcome: The client now benefits from a sophisticated digital method for viewing job progress directly on their manufacturing machines. This setup has significantly improved their ability to monitor and manage operations in real time, enhancing overall efficiency and productivity.

This case study highlights our capability to deliver tailored IT solutions for specialized industrial applications, ensuring our clients receive the best possible support and technology to meet their unique operational needs.

Business IT Support

Business IT Support Managed Backups

Managed Backups Cybersecurity

Cybersecurity Microsoft 365

Microsoft 365 Server Management

Server Management